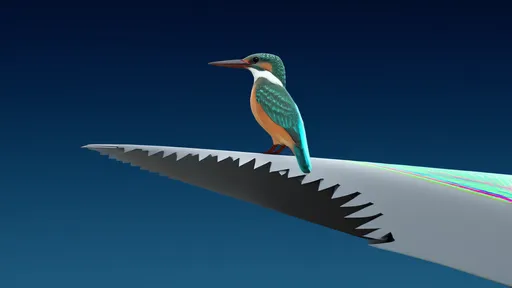

The aviation industry has long sought innovative ways to reduce fuel consumption and minimize environmental impact. One of the most promising breakthroughs in recent years comes from an unlikely source: shark skin. Inspired by the unique texture of a shark's dermal denticles, scientists and engineers have developed aircraft coatings that mimic this natural design, resulting in a measurable 5% improvement in fuel efficiency. This advancement could revolutionize commercial aviation, offering significant cost savings and reducing carbon emissions on a global scale.

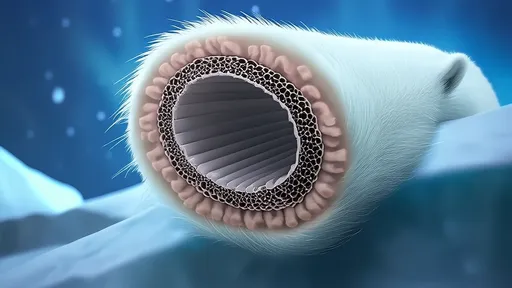

Sharks are among the most efficient swimmers in the ocean, thanks in part to their rough, textured skin. The microscopic ridges on their scales, known as denticles, reduce drag by manipulating water flow around their bodies. Researchers at Fraunhofer Institute for Manufacturing Technology and Advanced Materials in Germany first explored how this principle could be applied to aircraft. By replicating these microscopic patterns on adhesive films, they created a surface that disrupts turbulent airflow over an aircraft's wings and fuselage, effectively reducing friction and improving aerodynamics.

The implications of this technology are profound. A 5% increase in fuel efficiency may seem modest at first glance, but when applied across an entire fleet of aircraft, the savings become staggering. For a major airline operating hundreds of flights daily, this could translate to millions of dollars in reduced fuel costs annually. More importantly, it represents a substantial decrease in CO2 emissions—a critical step toward meeting international climate goals. Airlines are under increasing pressure to adopt greener technologies, and shark skin coatings offer a practical solution without requiring expensive redesigns of existing aircraft.

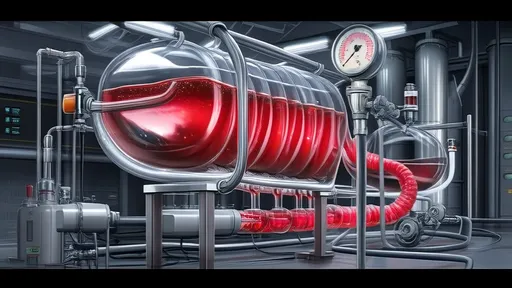

Testing the coatings in real-world conditions presented its own set of challenges. Engineers had to ensure the material could withstand extreme temperature fluctuations, high-speed airflow, and prolonged exposure to ultraviolet radiation. After years of development, the final product proved remarkably durable. Lufthansa became one of the first major carriers to trial the technology, applying the riblet films to select aircraft in its fleet. The results confirmed laboratory findings, with consistent fuel savings observed across various flight conditions.

Beyond commercial aviation, military organizations have taken notice of the potential benefits. The U.S. Air Force Research Laboratory has explored similar drag-reduction technologies for fighter jets, where even marginal improvements in efficiency can extend operational range or increase payload capacity. Naval architects are also investigating applications for ships and submarines, where hydrodynamic resistance plays an even greater role in performance. The biomimicry of shark skin appears to have far-reaching applications across multiple transportation sectors.

Manufacturing the coatings at scale required innovative approaches. Traditional methods of etching microscopic patterns proved too slow and expensive for mass production. Engineers developed a roll-to-roll embossing process that could imprint the precise riblet patterns onto large sheets of polymer film at high speeds. This breakthrough in manufacturing technology made it economically viable to outfit entire aircraft fleets with the drag-reducing surface. The films are applied much like large decals, allowing for relatively easy installation and replacement when necessary.

While the technology shows great promise, some limitations remain. The films are most effective on smooth surfaces, meaning they provide less benefit on aircraft with extensive riveting or surface irregularities. Maintenance procedures must also be adapted to preserve the delicate microstructures during cleaning and repair operations. Researchers continue to refine the technology, experimenting with different pattern geometries and materials to optimize performance across various aircraft types and flight conditions.

The environmental benefits extend beyond reduced fuel consumption. By decreasing drag, the coatings allow aircraft to operate at slightly lower engine power settings, which reduces noise pollution near airports. This secondary benefit could help alleviate one of the most persistent complaints from communities surrounding major air transportation hubs. As noise regulations become increasingly stringent worldwide, such ancillary advantages may prove just as valuable as the direct fuel savings.

Looking ahead, researchers speculate that further refinements could push efficiency gains beyond the current 5% benchmark. Some experimental designs incorporating adaptive surfaces that can alter their texture in response to changing flight conditions show particular promise. These "smart" coatings would optimize drag reduction throughout all phases of flight, from takeoff to cruising altitude to landing. Such advancements would build upon the foundational work done with static shark skin-inspired films.

The aviation industry's adoption of biomimetic technologies like shark skin coatings represents a broader trend toward nature-inspired engineering solutions. From whale fin-shaped wind turbine blades to termite mound-inspired building ventilation systems, engineers increasingly look to biological adaptations that have been refined over millions of years of evolution. In the case of shark skin aircraft coatings, this approach has yielded tangible benefits that address two of aviation's most pressing challenges: operating costs and environmental impact.

As the technology matures and production costs decrease, widespread implementation appears inevitable. Regulatory bodies have begun establishing certification standards for the coatings, clearing the way for broader adoption. With global air travel demand continuing to rise, solutions that make aircraft more efficient without compromising performance will be crucial for sustainable growth. The humble shark, often feared as a predator of the deep, may ultimately become an unlikely ally in humanity's quest for greener aviation.

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025